CLIP: The New Game-Changing Layerless 3D Printing Technology

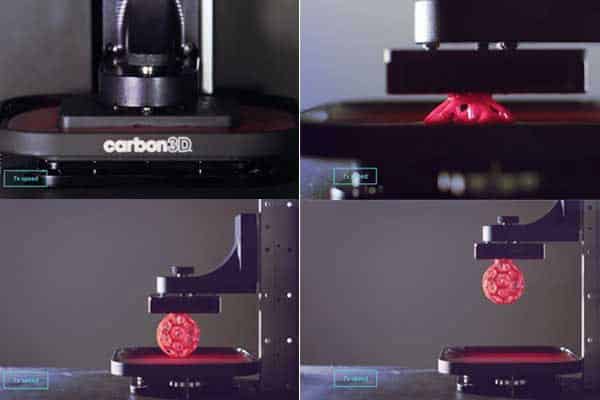

The 3D printing technology is evolving very rapidly as companies and startups continue to develop new innovative ideas to take new technology from the prototyping phase to the industrial and mass production levels. Investigations and research are taking place not only in the implementations of 3D printing technology but also in overcoming the barriers faced by the technologies used in the 3D printing process. Recently, Carbon 3D presents a new technology that can take 3D printing to a new level in terms of the speed and the quality of the output. The new technology is known as Continuous Liquid Interface production (CLIP).

Currently, the 3D printing industry depends on four technologies used in the printing process. These techniques include the following:

Fused Deposition Modeling (FDM) – this technology is used in most desktop 3D printers and depends on using flint, plastic or mixed materials that are heated and exuded through the printer head to build the 3D model layer by layer. This technology is affordable but have low quality output and prints using a one color filament.

Powder printing – this technology depends on building the 3D model by adding layers of powder on top of each other while connecting them with special glue. While this technology is expensive, it produces a high quality output with wide range of color choice.

Stereolithography 3D printing – this technology uses liquid photopolymer (Resin). The laser beam moves through the Resin and starts to trace the 3D model, the beam turns the liquid material into a solid model. This technology is advantageous due to its speed printing however the price for the photopolymer is expensive compared with other materials.

Selective laser sintering – this technology merges powder 3D printing and stereolithography. The laser bean shapes the model using a combination of two powders. This technology allows creating complex shapes that were not possible to print using the other technologies.

The Continuous Liquid Interface production (CLIP)

The above technologies are faced with number of barriers such as the longer times required to print small models and the quality of the output. The new technology uses both light and oxygen as a tool to build the object from a pool of liquid resin by forming the model layer by layer similar to additive manufacturing.

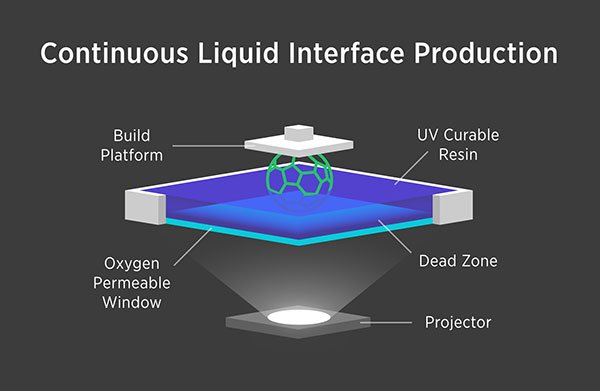

In the new technology, the mechanical steps that were previously used to build the model layers are eliminated. Instead, the light is projected through oxygen-permeable window into the reservoir of the UV curable resin. The head of the 3D printer lifts as the model is built using the liquid resin. The oxygen-permeable window is transparent and works similar to contact lenses. By controlling the oxygen flow through the window, thin layers are created from the incurable resin. The model is built from the resin using the UV image that is projected using special software.

Advantages of Using the CLIP 3D printing

The new CLIP technology tends to solve some limitations of existing technology through achieving the following three main advantages:

- High speed printing that functions 25 to 100 times faster than the existing technologies

- High quality printing as a result of eliminating the mechanical layer-by-layer building process

- Wider choice of materials and colors through the usage of polymeric materials

Dr. Joseph DeSimone, CEO and co-founder of Carbon 3D, explains the advantage of the new technology as the current technologies failed to propel the industry forward due to the very slow production time. The new technology aims to increase the printing speed with higher quality and a wider variety of colors and materials.

While the 3D printing speed using the stereolithography 3D printing (SLA) method can take up to 11:30 hours and 3:30 hours in the selective laser sintering (SLA), the CLIP technology can reduce this time to only 6:30 minutes using the same model.

In the last few years, companies and start-ups were focusing on the implementation of 3D printing technology through the same printing techniques again and again. Most of the project results were facing similar problems such as quality, printing speed, variety of colors and materials. These problems were actually related to the base technology used in the printing process. The Carbon 3D new technology is one of the pioneer projects that strives to address these issues by providing a game-changing technology that can overcome these problems.

The new technology provides an example of how to implement creative thinking by mind mapping the problem in order to reach innovative solutions (Using the TRIZ Method for Creative Problem Solving).