What is the Failure Mode and Effects Analysis (FMEA)?

Our worst fear in design is to end up with a failed product (at least for some). At this particular moment, we pause and wonder; if we knew this was going to happen, we could have taken another route. The Failure Modes and Effects Analysis (FMEA) tool helps us to understand the potential risks that may occur when the consumers use the designed product or service and provides suggested methodologies to prevent it in an early stage of the design process.

Related articles:

Problem-Solving Using Cause and Effect Diagram

Using the TRIZ Method for Creative Problem Solving

Practice Guide to Solve Problems with TRIZ

What is the Failure Mode and Effects Analysis (FMEA)?

he Failure Mode and Effects Analysis provides a proactive method that allows us to evaluate both the design and the process to learn more about when, where, and how the failure may occur. Also, it shows us the impact of failure on different parts of the process by prioritizing the risks using three main values: the Severity of the risk, its Occurrence, and the ability to detect it. Then, the team can apply problem-solving tools such as the SCAMPER technique, TRIZ or 8D Problem-Solving Approach.

The Failure Mode and Effects Analysis were first introduced by the U.S. Department of Deference in 1949, and it is now widely used in quality control. It is built on other tools, such as Risk Analysis and the Cause-Effect diagram. It can be used in both the product development process and the business design process.

The Types of the FMEA

The Failure Mode and Effects Analysis can be categorized based on the target part of the production. So, we can categorize the FMEA into the following types:

- Design FMEA explores product malfunctions related to materials, form, interface components, and engineering. These failures may affect factors such as the product life cycle and safety.

- Process FMEA explores the faults related to the production process, including the manufacturing and bringing all the industry components together.

- Functional FMEA explores the faults in how the global system functions

- Service FMEA involves the service design associated with the product

Some added more types to the above list, such as the System FMEA and the Software FMEA. However, the above categories can cover all the possible types of Failure Mode and Effects Analysis.

What are the benefits of the FMEA?

While testing and evaluating the design prototype, several factors can’t be accurately defined unless the product is released and understood from the larger context of user experience, the context of use, technology, economy, and the usage intersection with other products. So, we can benefit from utilizing the FMEA risk analysis to:

- Identify and eliminate the risk of potential product problems

- Improve product safety and reliability

- Rescue the cost of the problem fixing in the future product improvement process.

How to Apply the Failure Mode and Effects (FMEA) Process?

The Failure Mode and Effects Analysis is applied in different stages of the product, for example, at the beginning of a new production process, applying changes to an existing product or the production process, applying new production regulations, and, of course, to solving a problem reported by the consumer about the product.

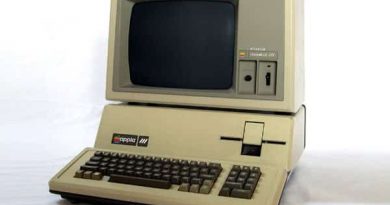

The application of the Failure Mode and Effects Analysis can be made through a number of procedures that are organized in a table as follows:

Setup Stage

This stage starts with defining the stakeholders who will be involved in the Failure Mode and Effects Analysis process. The stakeholders must represent the different departments that can advise in relation to the product’s potential risk of failure. Then, the team defines the FMEA process’s scope and the investigation’s scope.

Configuration Stage

The aim of this stage is to configure the process by defining the functions of the product that will be assessed and the potential failures that may occur while using the product in relation to each function.

Once the failures were identified, each failure’s consequences were defined before conducting each failure’s consequences were defined before conducting the risk assessment for each failure.

Risk Assessment Stage

In this stage, the FMEA tool is used to determine the risk priority number (RPN) for each failure mode as follows:

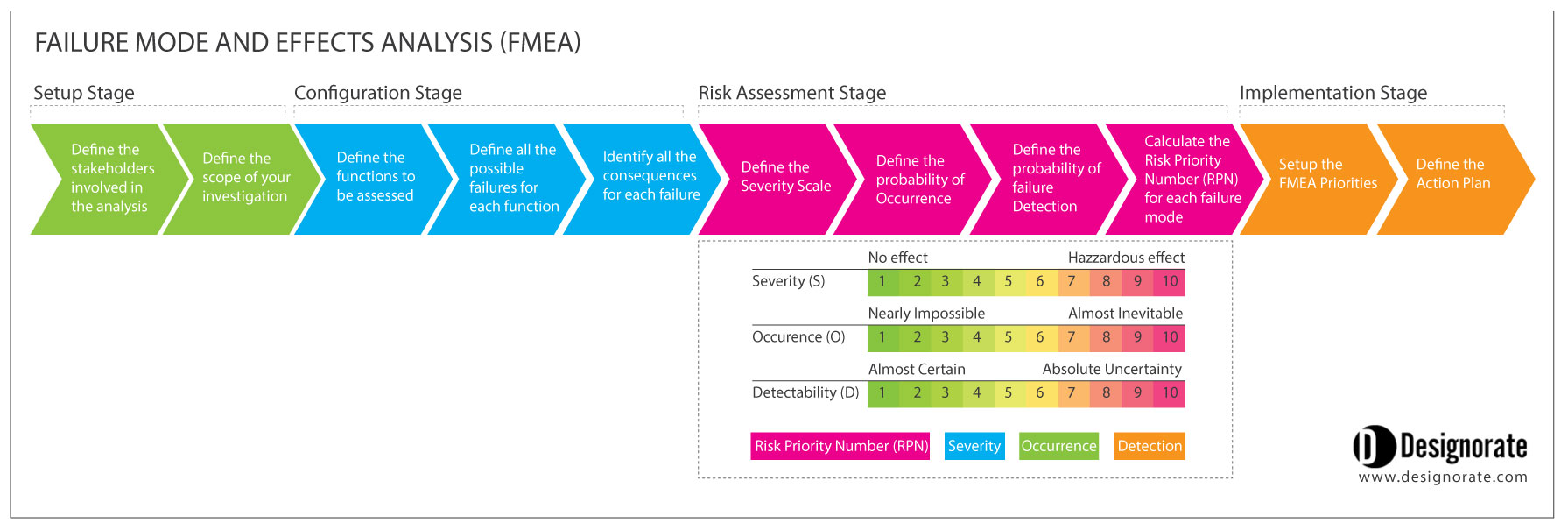

1) FMEA Severity Scale

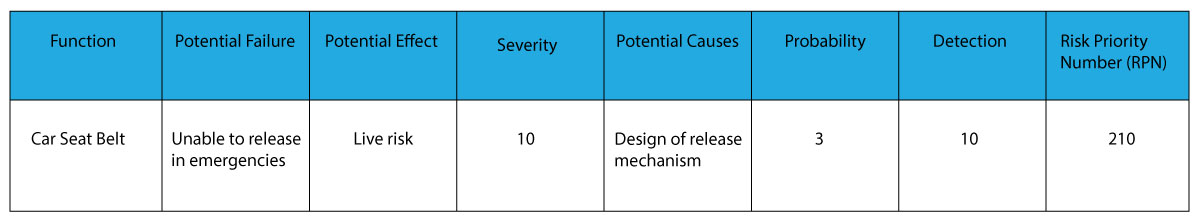

Define the first potential failure that may occur in the product design and process. Each potential failure should be listed individually to avoid distraction and misleading information. In the best example, it is hard to release in time for emergencies that require leaving the car immediately, such as drowning or fire.

Determine the severity level of the fault effect. The standard scale is from 1 to 10, where 1 refers to no effect, and 10 means a high probability of failure affecting the product or system without warning. In our example, the severity level is 10.

Add the potential cause or causes for the failure. For example, the design of the seat belt lock, the functionality of the lock and how easy it is to open it when the user intends to do that.

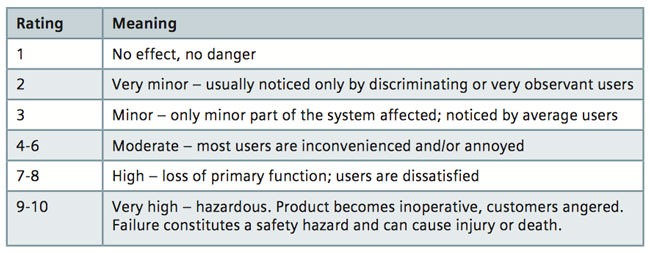

2) FMEA Probability of Occurrence

Add the probability factor, which represents how many times this failure is likely to happen. Again, the common scale is from 1-10, where 1 means that the fault is not likely to happen and 10 means that there is a high probability to occur. In this case, the probability will be 3 as it is assumed that there is a lower number of accidents that may occur and require an immediate release to the seat belt.

Identify the current procedures that the system is using to prevent such failures from happening, such as testing, monitoring, or applying error-prevention mechanisms. For example, the current lock is designed to be easily released. Its red colour allows the user to easily identify it.

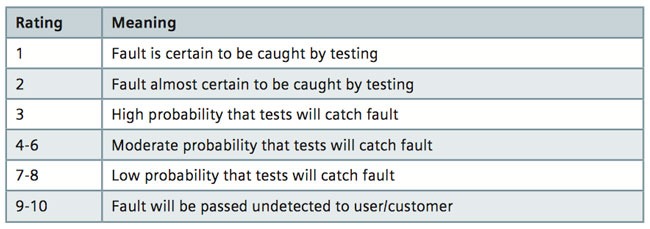

3) FMEA Failure Detection

Determine the detection value for the fault. It represents the likelihood of detecting the failure using the current control methods. We use a scale of 1-10 to determine the detection value. However, it is a reversed value compared with the above factors. This means that 1 refers to the error likely to be detected using the current controls and mechanism. The 10 value means that the fault is not likely to be detected. In our example, we will set the detection value to 7 as the testing machine may not involve testing how the drivers release the belt during the time of accidents.

4) Calculate the Risk Priority Number (RPN)

Define the Risk Priority Number (RPN) for failure. The RPN is an equation that includes multiplying the above three factors to prioritize the faults and decide and understand the importance of solving them. The RPN equation is:

Risk Priority Number (RPN)= Severity x Occurrence x Detection

In our example, the RPN= 10 X 3 X 7= 210

The Implementation Stage

Once the RPN number is calculated for all the potential failures, the team sets up a priority for all the failures. It determines the recommended actions that can be applied to prevent these failures in the future. This may involve changing the current controls or improving them to ensure that the detected failure will not occur again. For example, changing the position of the lock to make it easier to release during emergencies.

Assign the responsibility of applying the recommended procedures to a person in order to build an action plan to apply these recommendations within the current system structure.

Repeated the above steps with each detected failure. Using the Risk Priority Number, you can determine which fault is more severe than the others and which one to start solving immediately. The table above shows a complete Failure Mode and Effects Analysis that is done to explore solutions for a number of failures in a product. You can use it as a template for future FMEA tasks.

The Failure Mode and Effects Analysis provides a systematic method to detect, analyze and provide a solution for failures that may occur on multiple levels of the production process. It helps the team to indemnify the weak points in the product, process, or system and try to overcome them over the course of improving the production process and, subsequently, the final product or service.

Bibliography:

Carlson, C., 2012. Effective FMEAs: Achieving safe, reliable, and economical products and processes using failure mode and effects analysis (Vol. 1). John Wiley & Sons.

Mikulak, R.J., McDermott, R. and Beauregard, M., 2017. The basics of FMEA. CRC press.